Drop Ship Sale Order

Satisfying the customer demand through third party vendors.Drop shipment on the

other hand is a method of order fulfillment where the organization taking the order

does NOT maintain their own inventory for the drop shipped product, but fulfill their

orders through 3rd party vendors who directly ship to the end customer ordering the

product.

NOTE: Supplier directly ships material to the customer.

Step 1

Define the item and apply template to the item, assign the item to all organization.

Enter list price in purchasing tab.

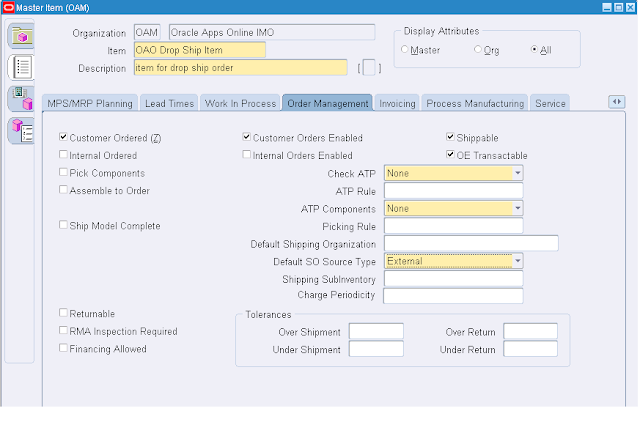

Source type should be external, Set it in Order Management tab as shown below.

We can set source type as external in three levels

Item level, Transaction level, Sales Order line level.

Assign item to all the organizations as shown below

Step 2

Create Sales Order and Book the sales order with source type as external

Initial status is entered

Check the Header status is Booked

Check line level status is also Booked

Step 3

Run workflow background process to move the data from OM base table to PO Interface table.

Check the request completed

Header Status Booked

Line status is Awaiting receipt

Step 4

Switch to Purchasing responsibility Run the Requisition import program

Check the request and view the output

Step 5

Find the requisition number

here we have two ways to find the requisition

a) query the sales order go to line level click on action select the additional line information to click on drop ship tab see the requisition number

b) go to requisition summary enter the item name click on find

See the requisition number as shown below

Step 6

Based on generated requisition number,crate purcahse order through auto create

process and approve it

Select the line click on Automatic

Click On Create

Note the PO number and Approve it

Click on OK

Check the PO Status

After PO Approved we have additional tab (Drop Ship) in PO form as shown in below

Step 7

Open the periods in Purcahsing responisbility to do the misclleanies receipt

Chage the Period status never opned to open

Save the changes

Select the ledger and click on find

Click on Open Period

Step 8

Do the logical Receipt againest the Purchase Order

Enter the po number

Select the line Chose the subinventory and save it

Check the request Completed

Here we can see the Receipt number

Check the on hand quantity

Query the sales order check the line staus

Thats All about Drop Ship Sales Order